Welcome to Linyi Kemele Co., Ltd

The Application of Sodium Thiocyanate

(1)(1).png)

Product Overview

Sodium thiocyanate is a colorless crystal containing 2 parts of crystal water. At 30.4℃, the crystal water is lost to become anhydrous sodium thiocyanate, soluble in water and ethanol. It is produced from azeotrope of sodium cyanide and sulfur slurry in industry, and is one of the purification products of coke oven gas in coke plant, and is produced from waste liquid of anthraquinone disulfonic acid process. Sodium thiocyanate is used in printing and dyeing and pharmaceutical industries, and is also used as a reagent and a solvent for polyacrylonitrile.

preparation technology

1) Sodium cyanide sulfur synthesis technology

Sodium thiocyanate is synthesized by one step reaction with sodium cyanide and sulfur powder as raw materials. After impurity removal, decolorization, filtration, filtrate evaporation, crystallization, centrifugal separation and drying, sodium thiocyanate is obtained. The reaction equation is as follows:

The advantages of this process are high purity, good quality and stable product quality. The disadvantage is the use of highly toxic chemicals: sodium cyanide, and its purchase, transportation, and use have strict restrictions. The use process has a certain risk, we must strengthen the investment in safety facilities and emergency measures, and strictly implement the "five double" management system of serious drugs.

2) ammonium thiocyanate conversion method

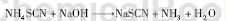

Ammonium thiocyanate and sodium hydroxide are used as raw materials to obtain sodium thiocyanate through double decomposition reaction, and then through impurity removal, decolorization, filtration, filtrate evaporation, crystallization, centrifugal separation and drying to obtain sodium thiocyanate products. The reaction equation is as follows:

The advantage of this process is that the production process is simple and easy to operate. The disadvantage is that the quality of the product is greatly affected by the quality of the raw material ammonium thiocyanate, and high-quality ammonium thiocyanate must be used to produce high-quality sodium thiocyanate, and the cost of synthesizing high-purity ammonium thiocyanate is often higher. The coking desulphurization wastewater with HPF process often contains a certain concentration of ammonium thiocyanate, which will have a serious impact on production and equipment if it is not recycled. Ammonium thiocyanate was extracted from the wastewater, which not only treated the wastewater, but also obtained ammonium thiocyanate. This ammonium thiocyanate cost is low and can be used in the production of sodium thiocyanate. At present, more and more enterprises choose to use this process to produce sodium thiocyanate.

Application in organic synthesis

1. Synthesis of methyl dithiocyanate

Methyl dithiocyanate is an important organic synthesis intermediate, which can be used in the synthesis of a variety of medicines, pesticides and other fine chemicals. The synthesis method is as follows: After 24.5g sodium thiocyanate is dissolved by adding 55mL distilled water, 30mL dimethyl sulfate is added in the stirring state, and the drop temperature does not exceed 60℃ for 2h. After standing for 12h, the reaction liquid was filtered with Bush funnel, separated the organic phase, washed with water three times, 16mL light brown oily liquid was obtained, with pungent odor. Then dry with anhydrous sodium sulfate after distillation, collection of 131 ~ 132℃ fractions is the finished product. The synthesis of methyl dithiocyanate from sodium thiocyanate has the characteristics of low cost and easy to master.

2. Synthesis dithiocyano-methane

dithiocyano-methane is used in the manufacture of rubber products such as cables, wires, tires, and is also an efficient, broad-spectrum bactericidal algaecide. The synthesis method is as follows: 81g sodium thiocyanate is dissolved with 200g distilled water, the temperature is raised to 90℃ and 80g dibromomethane is added, the drop is completed for 1h, and the reaction is continued for 2h. Cool to 25 ° C, strain and wash in distilled water until bromine-free. Dry. The content of dithiocyanomethane in the product is above 95% and the yield is above 8%.

3. Synthesis methyl isothiocyanate

Methyl isothiocyanate can be used to synthesize the pesticide methyl tolbuzine. The synthesis method of methyl isothiocyanate was as follows: 81g sodium thiocyanate, 200g ethyl acetate was added to dissolve, the temperature was kept below 15℃, 95g methyl chloroformate was added, and the reaction was continued for 2h. The organic phase is separated, washed with water until no chloride ion is present, and then dried with anhydrous sodium sulfate. Store below 20℃. Shelf life within 1 month.

4. Synthesis Benzyl thiocyanate

Benzyl thiocyanate can be used in the preparation of insecticides. The synthesis method was as follows: 2mL benzyl chloride, 12g sodium thiocyanate aqueous solution (16.7%) and 0.4g β-cyclodextrin were added into 50mL four-mouth round-bottom flask. Heat to 100℃ and react for 2h. Cool the reaction mixture to 25 ° C. Extract with 20mL ether twice. The organic phase was washed twice with distilled water to remove the inorganic salts, and the ethyl ether was removed by distillation to obtain a brown yellow oily liquid. After cooling and solidification, white riblike benzyl thiocyanate was obtained by recrystallization with ethanol.

Main reference material

[1] Encyclopedia of Chinese Metallurgy · Coking Chemical Industry

[2] Progress in the process of extracting sodium thiocyanate from desulfurization waste liquid

[3] Study on the synthesis technology of sodium thiocyanate and its application in organic synthesis

Next: None